Tenemos una larga trayectoria suministrando overoles desechables a una amplia gama de industrias donde el control y la eliminación de la contaminación es fundamental para el proceso de producción y la calidad de los productos fabricados.

While protective suits and garments in a cleanroom may look very similar, the most important factor is how they perform against the conditions you are faced with in the cleanroom. DuPont™ Tyvek® 500 Xpert Hooded Coverall is made of the ideal material for an applications requirement for a low-linting garment such as pharmaceuticals - its strong high density polyethylene fibers means it doesn't shed fibers. Also, the open structure of the garment shows the best breathability performance while not compromising the protection performance - Tyvek® offers the best balance of comfort and protection. In comparison to microporous film, it removes humidity significantly faster. Tyvek® is the only type 5/6 coverall on the market with superior particulate protection, an ergonomic design for enhanced protection and it can be eco-packed to provide a more sustainable packing alternative, including limited use of plastic and paper. DuPont™ as a company have many policies and tests to determine to quality level of their product, and have a criteria that each product must pass - these are: be safe for use, correctly labelled to avoid misuse meet performance marketing claims, with the support of technical data composition verification for carcinogens and do not contain REACH substances or DMF allergy testing must be conducted and a latex review by a toxicologist minimise environmental footprint ensure packaging and production meets the highest ethical and environmental standards.

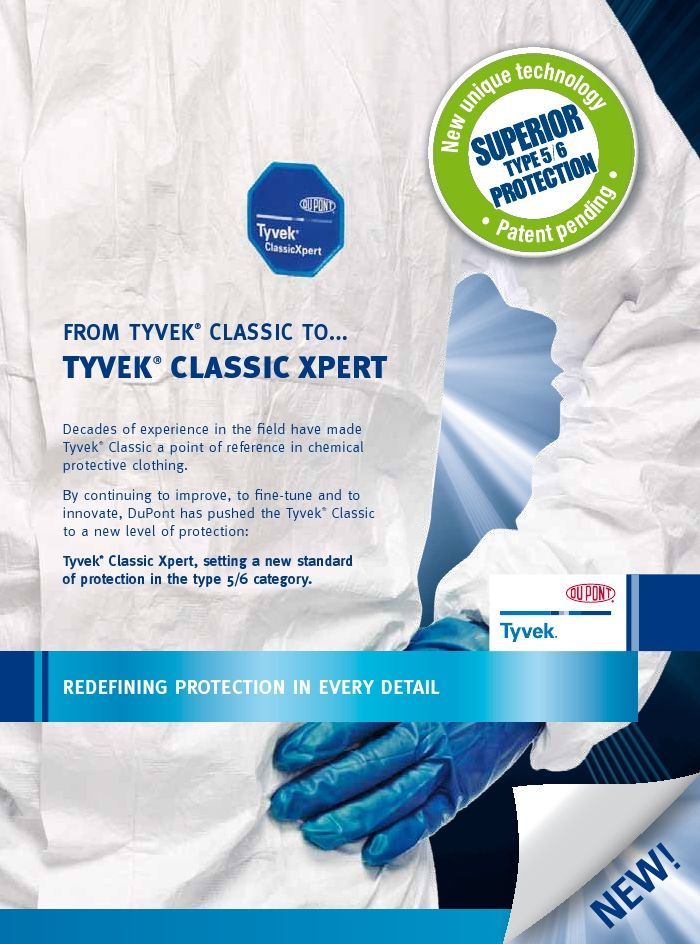

With almost 60 years in the industry, lightweight and durable, Tyvek® is breathable, yet resistant to water, abrasion, bacterial penetration and aging, making it ideal for a wide variety of applications across diverse industries. DuPont is a global leader with Tyvek® protective garments providing superior protection for workers in industrial and cleanroom applications and for first responders. Companies around the world use more than 200 million Tyvek® garments per year. Tyvek® garments have been used to support emergency response efforts across the globe, making it the perfect partner for protection in critical conditions. Beyond protecting homes and workers, Tyvek® also is widely used to help protect patients in healthcare settings. Since its introduction to the medical device industry more than 45 years ago, Tyvek® has been recognized as a standard of excellence for sterile device packaging. Tyvek® earned this distinction because it provides excellent microbial barrier, strength and protection for medical devices and pharmaceutical applications. DuPont Tyvek® has been on quite the journey since it's discovery, see more about how it has evolved over time. 1955: The history of Tyvek® began in 1955 when DuPont researcher Jim White made a chance discovery of a new fiber source. A program to develop the new material was set up and a year later DuPont submitted a patent proposal for strong yarn linear polyethylene. 1967: DuPont opens its first production line in Virginia, USA. New revolutionary applications include medical packaging and protective garments. 1988: DuPont opens its second Tyvek ® production line in Luxembourg. The facility is certified to ISO 14001 in 2004, and ISO 9001 in 2008. 2005: Tyvek ® is the first manufacturer to claim CE marking for its entire product range. Tyvek® products have earned numerous awards for innovation and performance from organisations in all regions of the world. Most recently: • Tychem® 6000, a protective apparel garment that provides triple hazard protection from chemicals, flash fire and electric arc, received the 2016 Innovation Award at the Fair Préventica in Lille, France. • Tyvek® 800J, a protective apparel garment that combines resistance to low-concentration, water-based, inorganic chemicals with the durability of Tyvek®, received the 2014 Innovation Award at the Fair Préventica in Marseille, France. Whether it’s keeping homes comfortable, protecting workers from on-the-job hazards, enabling a safe response to epidemics, or countless other applications—the unique attributes of DuPont ™ Tyvek ® bring comfort, protection and the gift of life to millions each day. Tyvek ® personal protection equipment delivers performance that meets or exceeds industry standards for protection against a range of chemical threats and hazards.

Microzone offer a comprehensive range of disposable workwear for use in low grade cleanrooms, hospitals and controlled manufacturing environments. The PG32 is a Microzone Non-woven Coverall with Hood, made from 100% Polypropylene. The Coverall has a zip fastening and no pockets with an e lastic wrist, ankle and elastic back of waist. Packaging details: Inner Packing 5pcs/polybag Export Carton 10 Bags/Carton Carton Dimension 48 x 30 x 42cm – 50 piece For more information please contact sales@cesltd.uk.com