Close the Gaps in Contamination and Get Dressed for Success

Close the Gaps in Contamination and Dress for Success with Kimtech™

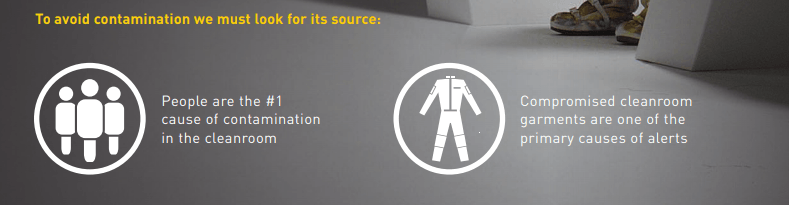

The results of such contaminations are significant and lead to billions of dollars being wasted each year in write-offs, shutdowns and lost productivity.

The wide range of issues resulting from contamination control that have been explored in this article are multi-faceted, and require a mitigation approach that addresses all aspects of clothing use and disposal. Documented and enforced training programs, verified ongoing adherence to the latest regulatory compliance, and effective disposal and recycling procedures can all be combined to create a safer, more productive and sustainable operation. High quality clothing design plays a vital role in this.

Kimtech™ A5 Sterile Cleanroom Apparel has been designed to provide this solution. The Kimtech™ SMS (Spunbond/Meltblown/Spunbond) fabric provides strength, cloth-like comfort and a strong barrier for fine particles and liquids. Its middle layer acts like a filter which traps particles while maximising airflow to keep the wearer cool and comfortable. In addition, the sterilisation process, involving gamma irradiation of the polymers, occur on only a single garment at a time, so the apparel’s protective properties are consistently maintained. By demonstrating how optimised cleanroom clothing can reduce contamination and form part of a system that produces better results at a lower cost, Kimtech™ aims to support continuous improvement across the Pharmaceutical industry.

Well-designed disposable cleanroom garments have been shown to be cost-effective and sustainable, while also providing improved contamination protection and greater comfort for pharmaceutical cleanroom operators. Cutting down on the human based causes of contamination leveraging disposable apparel leads to increased productivity and a reduction in operator training requirements, cleanroom downtime and drug shortages – truly assisting modern cleanrooms to dress for success!