Comparing and Selecting Chemical Protective Garments

18 November 2020

Not every manufacturer gives you the full picture.

Not all garment manufacturers publish permeation data. For example, they provide no information about how the garment performs in permeation tests.

DuPont, on the other hand, publishes permeation data for our chemical resistant/secondary flame-resistant garment fabric, Tychem® 2000 SFR.

Bottom line?

If chemical protection is your need, permeation is your test. Make sure you know the type of test that was conducted on your garments.

Comparisons can be confusing.

When you're considering how long garments can be worn before chemical breakthrough, it's important to understand the type of permeation testing that has been performed on them.

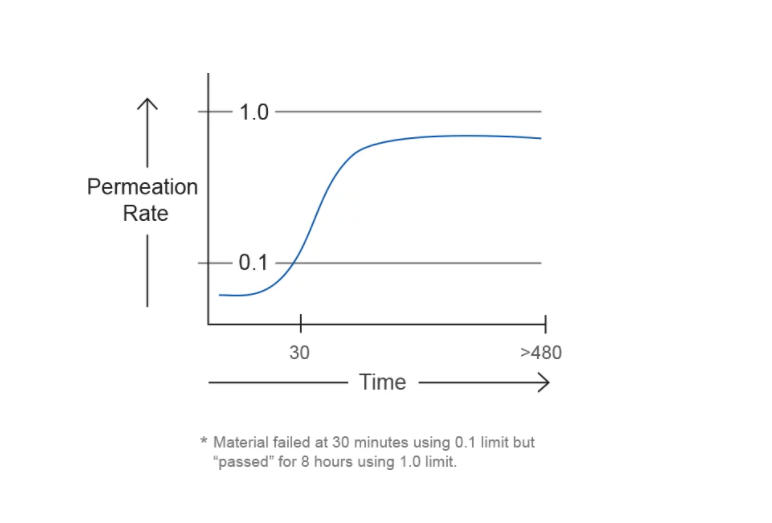

ASTM F739 specifies that results should be recorded at a normalized breakthrough time (NBT) of 0.1 µg/cm2/min. DuPont tests all Tychem® fabrics using this method. ASTM F739 is the standard test used in North America. Another commonly used permeation test uses an NBT of 1.0 µg/cm2/min., a rate used in Europe per EN ISO 6529. The ASTM F739 method, the method DuPont sites, is the more stringent and sensitive test for chemical permeation, because it defines breakthrough at a 10x lower threshold.

Bottom line?

When deciding on protective garments, make sure you're comparing fabrics that are tested at the same permeation rate limits. Seek data for the specific chemicals you work with.

Not everything is what it "seams"

Seams make a big difference in the overall protection a garment provides.

Some competitors may compare performance of a taped or bound seam garment to that of a serged seam garment.

That's not an honest, "apples-to-apples" comparison. Performance comparisons should always be made between garments with similar seam constructions. DuPont offers garments with different types of seams: serged, bound, and taped. When deciding which garment to purchase, make sure you compare garments with the same type of seams, and select a seam type that meets your hazard needs.

Focus on the fabric.

When you're reviewing competitors' claims of how their fabrics perform versus Tyvek®, pay attention to the fabric type.For example, the fabrics Lakeland and Kimberly-Clark compare to Tyvek® typically are made with either microporous film (MPF) or spunbond-meltblown-spunbond (SMS) fabric—neither of which has the unique properties of Tyvek®.

Engineered using proprietary, flashspun polyethylene technology, garments made with Tyvek® fabric provide many advantages versus the competition, including superior barrier protection after abrasion, durability and comfort.

To read more visit DUPONT

For our full range of Dupont Tychem products visit CES

To find out more about the brands we supply visit our brand page

While protective suits and garments in a cleanroom may look very similar, the most important factor is how they perform against the conditions you are faced with in the cleanroom. DuPont™ Tyvek® 500 Xpert Hooded Coverall is made of the ideal material for an applications requirement for a low-linting garment such as pharmaceuticals - its strong high density polyethylene fibers means it doesn't shed fibers. Also, the open structure of the garment shows the best breathability performance while not compromising the protection performance - Tyvek® offers the best balance of comfort and protection. In comparison to microporous film, it removes humidity significantly faster. Tyvek® is the only type 5/6 coverall on the market with superior particulate protection, an ergonomic design for enhanced protection and it can be eco-packed to provide a more sustainable packing alternative, including limited use of plastic and paper. DuPont™ as a company have many policies and tests to determine to quality level of their product, and have a criteria that each product must pass - these are: be safe for use, correctly labelled to avoid misuse meet performance marketing claims, with the support of technical data composition verification for carcinogens and do not contain REACH substances or DMF allergy testing must be conducted and a latex review by a toxicologist minimise environmental footprint ensure packaging and production meets the highest ethical and environmental standards.

With almost 60 years in the industry, lightweight and durable, Tyvek® is breathable, yet resistant to water, abrasion, bacterial penetration and aging, making it ideal for a wide variety of applications across diverse industries. DuPont is a global leader with Tyvek® protective garments providing superior protection for workers in industrial and cleanroom applications and for first responders. Companies around the world use more than 200 million Tyvek® garments per year. Tyvek® garments have been used to support emergency response efforts across the globe, making it the perfect partner for protection in critical conditions. Beyond protecting homes and workers, Tyvek® also is widely used to help protect patients in healthcare settings. Since its introduction to the medical device industry more than 45 years ago, Tyvek® has been recognized as a standard of excellence for sterile device packaging. Tyvek® earned this distinction because it provides excellent microbial barrier, strength and protection for medical devices and pharmaceutical applications. DuPont Tyvek® has been on quite the journey since it's discovery, see more about how it has evolved over time. 1955: The history of Tyvek® began in 1955 when DuPont researcher Jim White made a chance discovery of a new fiber source. A program to develop the new material was set up and a year later DuPont submitted a patent proposal for strong yarn linear polyethylene. 1967: DuPont opens its first production line in Virginia, USA. New revolutionary applications include medical packaging and protective garments. 1988: DuPont opens its second Tyvek ® production line in Luxembourg. The facility is certified to ISO 14001 in 2004, and ISO 9001 in 2008. 2005: Tyvek ® is the first manufacturer to claim CE marking for its entire product range. Tyvek® products have earned numerous awards for innovation and performance from organisations in all regions of the world. Most recently: • Tychem® 6000, a protective apparel garment that provides triple hazard protection from chemicals, flash fire and electric arc, received the 2016 Innovation Award at the Fair Préventica in Lille, France. • Tyvek® 800J, a protective apparel garment that combines resistance to low-concentration, water-based, inorganic chemicals with the durability of Tyvek®, received the 2014 Innovation Award at the Fair Préventica in Marseille, France. Whether it’s keeping homes comfortable, protecting workers from on-the-job hazards, enabling a safe response to epidemics, or countless other applications—the unique attributes of DuPont ™ Tyvek ® bring comfort, protection and the gift of life to millions each day. Tyvek ® personal protection equipment delivers performance that meets or exceeds industry standards for protection against a range of chemical threats and hazards.

Microzone offer a comprehensive range of disposable workwear for use in low grade cleanrooms, hospitals and controlled manufacturing environments. The PG32 is a Microzone Non-woven Coverall with Hood, made from 100% Polypropylene. The Coverall has a zip fastening and no pockets with an e lastic wrist, ankle and elastic back of waist. Packaging details: Inner Packing 5pcs/polybag Export Carton 10 Bags/Carton Carton Dimension 48 x 30 x 42cm – 50 piece For more information please contact sales@cesltd.uk.com

The past 12 months of the COVID-19 pandemic have bought about many changes and unprecedented challenges for the UK and the world. In the initial period of 2020, CES faced the challenge of meeting the growing need for critical protection and supplies in the fight against COVID-19. This demand has grown considerably but despite the huge difficulties the pandemic has thrown at us we have managed to find a way to continue to operate in both an efficient and pro-active manner. Moving into 2021, CES have been extremely well placed and have very close business relationships with a number of pharmaceutical manufacturing companies that have been contracted to manufacturer COVID-19 vaccines. The increasing demand for vaccine manufacturing in an effort to meet the governments aim to vaccinate everyone aged 18 or over in the UK with one dose by the end of July has meant the demand for sterile cleanroom consumables has increased considerably. CES are working closely with Dupont Tyvek® to ensure the demands for sterile cleanroom clothing and disposables are met in an effort to support the push to manufacture COVID-19 vaccines.

Increasing productivity while maintaining environmental quality and regulatory compliance is an important challenge for cleanroom teams and requires solutions that address the root causes of contamination events. There’s no doubt about it. Contamination is bad for business and especially so for an industry where cleanliness and purity is paramount. It can lead to shutdowns, recalls and loss of life. Not to mention that it puts manufacturers in a negative spotlight. Studies show that the behaviour and preparation of personnel is responsible for a large proportion of contamination issues in cleanrooms..

Any work with cytostatics requires the Cytostatic Protection of workers from the dangers of drugs (carcinogenic, mutagenic, reprotoxic impact). At the same time, it is important to protect the product against contamination from people. Cytostatics are used as drugs in cancer therapy (chemotherapy) to inhibit the multiplication of tumour cells and are also used increasingly to treat other diseases. However, their toxicity affects not only tumour cells but also healthy cells. To prevent hazards to staff while handling cytostatics, a range of suitable precautions must be taken. What applies to the handling of hazardous substances in general is also true for cytostatics, i.e. the highest priority must be placed on the full use of all technical and organizational measures. For instance, care must be taken to prevent the formation of cytostatic aerosols and dust and to avoid cytostatic contamination during production, preparation, provision, disposal, storage and transportation of such substances. Potential health hazards can be caused even by low-level contact with cytostatic substances. If there is any risk of contact, use of suitable personal protection equipment (PPE) is mandatory to ensure effective full-scale protection. PPE selection is commonly based on the findings and results of risk analysis, in addition to technical and organisational measures. These protective measures apply to all staff who come into contact with cytostatics, not merely during production and preparation, but also application, disposal, shipping and when being handled by cleaning and maintenance staff. Both cleanroom clothing and chemical protective clothing need to meet the same basic criteria for use in a cleanroom: the material must be low-linting, the design must be sufficiently tight and the danger of collecting particles on the surface of the garment must be minimised. To be suitable for dealing with cytostatics, such clothing must also be comfortable to wear, it must have good electrostatic discharge efficiency and sterilisation must be possible.

31% operators claim donning coveralls is the most difficult part of gowning. The Kimtech™ A5 Sterile Cleanroom Coverall has an intuitive folding and donning mechanism between areas such as the coverall, hood and over boot, along with an optimised donning process, reducing both contamination risk and the potential for human error.

Whether it’s keeping homes comfortable, protecting workers from on-the-job hazards, enabling a safe response to epidemics, or countless other applications—the unique attributes of DuPont™ Tyvek® bring comfort, protection and the gift of life to millions each day. Lightweight and versatile yet resilient and durable, Tyvek® defies convention so you can defy the odds. From personal protection and weatherization to packaging and transportation, Tyvek® rises to the challenge— keeping the elements out while letting life in.

For decades, DuPont innovations have helped save countless lives. DuPont scientists work tirelessly to invent new materials that are used to develop a large range of Personal Protective Equipment. These include leading brands such as Tyvek® and Tychem®, the industry-leaders for personal and chemical protective clothing. Dupont Tyvek ® Protective suits may look the same, but only from a distance. Check out Dupont Tyvek material advantages over Microporous Film and SMS here .